February 5, 2024 by

Pot Still Distillation

Traditional Pot Stills For Distillery

Traditional pot stills are a type of distillation apparatus used to distill liquors such as whisky or brandy. They operate on a batch distillation basis, as opposed to Coffey or column stills, which operate continuously.

Pot stills are typically made from copper, a material that is preferred due to its ability to remove sulfides produced during the distilling process.

Pot stills are known for producing spirits with rich flavors and aromas, as they do not separate congeners from ethanol as effectively as other distillation methods.

This results in spirits that retain more of the flavor from the wash. They are often used to produce full-flavored spirits like tequila, some Jamaican rums, mezcal, and many malt whiskeys.

Certain spirits, like single malt Scotch whisky and cognac, are legally required to be made on pot stills. The shape and size of a pot still can influence the final product. Common shapes include onion-shaped, lantern-shaped, and pear-shaped stills.

Some stills may also have a spherical bulge in the lower part of the neck, which increases surface area and heat emission. Pot stills can range in size, from small distilling units for home use to large commercial stills.

For example, the largest pot still ever used was in the Old Midleton Distillery, County Cork, Ireland, with a capacity of 143,740 liters.

Today, companies like Specific Mechanical Systems offer pot stills ranging from 500 liters to 10,000 liters.

Despite their inefficiency compared to column stills, pot stills are valued for their ability to produce high-quality spirits.

They are used in craft distilleries and are also popular among home distillers. Companies like Hillbilly Stills and Clawhammer Supply offer a range of pot stills for home distilling, including copper and stainless steel options.

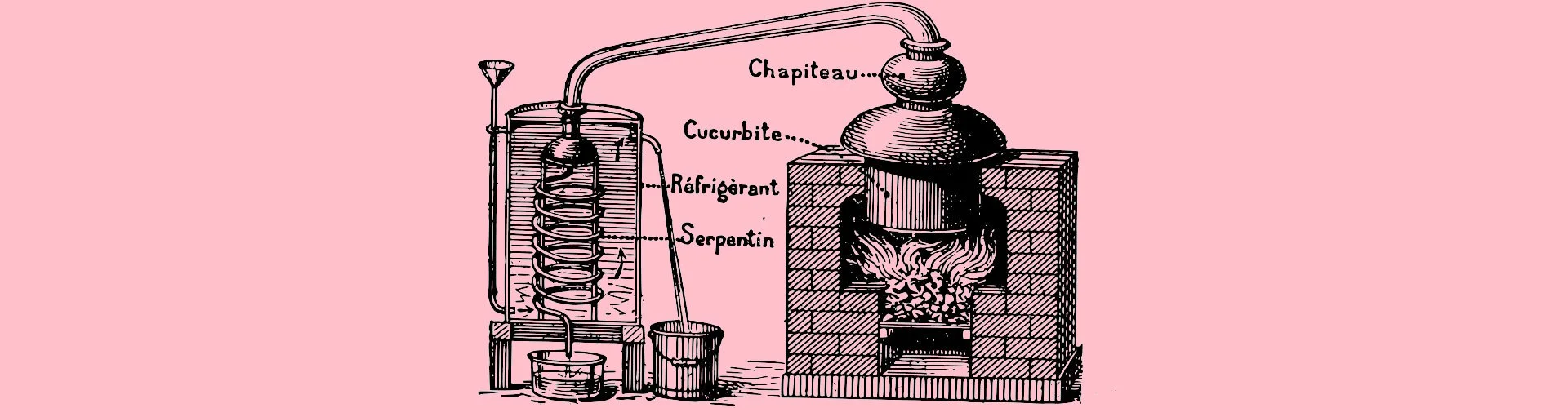

Diagram of Pot Still

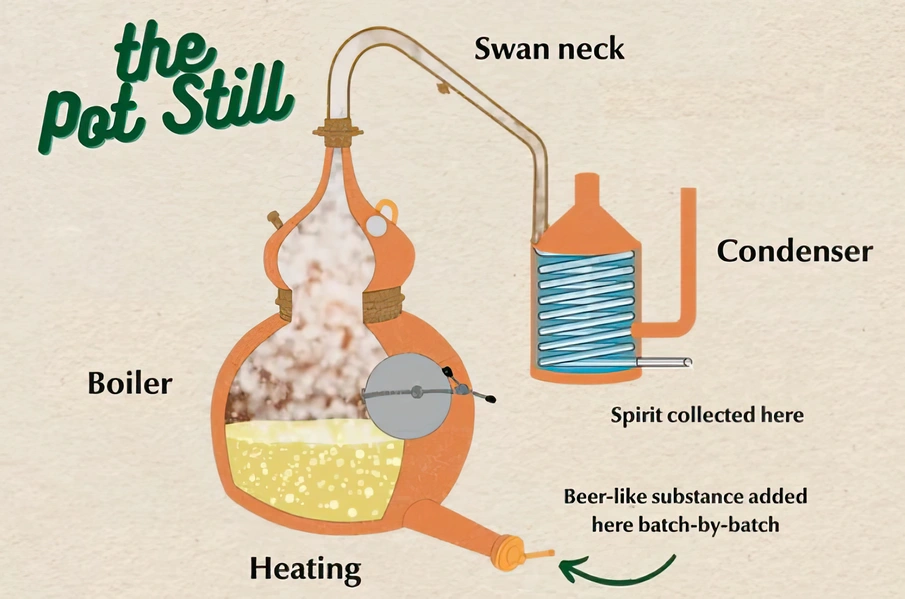

A traditional pot still is a type of distillation apparatus that consists of several key components:

- Boiler or Pot: This is the bottom part of the still where the wash (a beer-like substance) is heated. The pot is typically round in shape.

- Swan Neck or Lyne Arm: This is the long, tapered connection that links the pot to the condenser. When the wash is heated, alcoholic vapors rise into the swan neck.

- Condenser: This part of the still consists of a spiral tube surrounded by a cooling cold water jacket. The alcoholic vapors from the swan neck are cooled into liquid in the condenser.

The shape and size of the pot still can influence the flavor of the spirit. More contact with copper, which is the most common material for pot stills, results in a lighter and smoother liquor. Bigger and taller stills allow for more contact between the alcoholic vapor and copper, producing a lighter spirit. Conversely, shorter, smaller copper pot stills yield richer, heavier spirits. Here is a diagram of a traditional pot still:

Diagram of Traditional Pot Still

Image Source: Whisky Advocate

This diagram shows the key components of a pot still, including the boiler, swan neck, and condenser. The wash is heated in the boiler, causing alcoholic vapors to rise into the swan neck. These vapors are then cooled into liquid in the condenser.

What Is The Process Of Distillation Using A Pot Still

The process of distillation using a pot still involves several steps:

- Filling the Pot: The pot still is filled about two-thirds full with a fermented liquid, also known as the wash. This wash could be a beer-like substance for whiskey distillation or a base wine for brandy production.

- Heating the Wash: The pot still is then heated, causing the wash to boil. The heat can be applied through various means, such as a steam jacket lining the outside walls of the pot, a steam coil inside the pot, or a direct flame from a burner placed underneath the pot.

- Vaporization: As the wash heats up, the alcohol and other by-products of fermentation, known as congeners, vaporize. These vapors rise into the swan neck or lyne arm of the still.

- Condensation: The vapors are then passed into the condenser, where they are cooled and transformed back into a liquid. This liquid, now a concentrated alcoholic spirit, is collected.

- Separation of Fractions: The first part of the distillate, known as the “heads”, contains compounds that can be harmful or negatively affect the taste of the spirit. The middle section, or “heart”, contains the desirable, drinkable compounds. The last part, or “tails”, contains heavier alcohols and other compounds that can also negatively affect the taste. The distiller’s job is to cut off the heads and tails, keeping only the heart for bottling.

- Double Distillation: Often, the distillate is run through the pot still again to further concentrate the congeners and increase the alcohol content. This process is known as double distillation.

It’s important to note that the pot still is all about flavor. The focus is on the congeners, not just the alcohol. The final taste of a spirit like single malt whisky is likely about 70% congeners from the wash and 30% from the cask wood. The shape and size of the pot still can also influence the flavor of the spirit. More contact with copper, which is the most common material for pot stills, results in a lighter and smoother liquor.

How Long Does The Distillation Process Take Using A Pot Still

The duration of the distillation process using a pot still can vary significantly depending on several factors such as the size of the still, the type of spirit being produced, and the specific distillation techniques used.

However, based on various sources, a general estimate can be made. For home distillers, it can take around 2-3 hours to heat up a mash or wash in an uninsulated boiler. The actual distillation process can then take around 1 gallon per hour for the stripping run, and 1.5-2 liters per hour for the spirit run.

Another home distiller reported that a 6 to 8-gallon run takes about 1.5 hours for a stripping run, with a slightly longer time for a spirit run.

For larger scale distillations, it can take longer. For example, distilling 20 liters (5.3 US gallons) of water in a pot still can take about 8-10 hours from start to finish, excluding the heating time.

It’s important to note that these times are estimates and can vary based on the specific conditions of the distillation process. Factors such as the initial temperature of the wash, the heat source, the ABV of the wash, and the desired ABV of the final product can all influence the duration of the distillation process.